The Future of Metal Manufacturing: Trends and Technologies to Watch

Metal manufacturing has been a cornerstone of human progress for centuries, playing a crucial role in building everything from ancient monuments to modern skyscrapers. As we look to the future, this age-old industry is on the brink of transformation, driven by cutting-edge technologies and innovative approaches. In this blog, we’ll explore the key trends and technologies that are shaping the future of metal manufacturing.

- Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is revolutionizing the metal manufacturing industry. It enables the production of intricate metal parts with reduced waste and shorter lead times. The technology’s precision and flexibility have found applications in aerospace, automotive, and healthcare industries, among others. As 3D printing processes continue to advance, we can expect increased adoption in the production of metal components.

- Industry 4.0 and Smart Factories

The integration of Industry 4.0 principles into metal manufacturing is enhancing productivity and efficiency. Smart factories leverage automation, IoT devices, and real-time data analytics to optimize processes. This not only reduces production costs but also enhances quality control and supply chain management. With the growth of the Industrial Internet of Things (IIoT), metal manufacturers are better positioned to monitor, predict, and prevent equipment failures.

- Advanced Materials and Alloys

The development of new metal alloys and materials is opening up exciting possibilities in metal manufacturing. These advanced materials offer enhanced strength, durability, and resistance to corrosion. For example, lightweight yet high-strength alloys are transforming industries such as aerospace and automotive, where reducing weight without compromising safety and performance is paramount.

- Robotics and Automation

Robots have been steadily making their way into metal manufacturing, performing tasks that are either dangerous or repetitive for human workers. The use of robots improves precision, speed, and efficiency, especially in processes like welding, cutting, and material handling. As the technology advances, we can expect more widespread use of robots in various aspects of metal manufacturing.

- Sustainable Practices

As environmental concerns continue to gain prominence, sustainable practices in metal manufacturing are becoming a top priority. Companies are exploring cleaner and more energy-efficient production methods. Recycling and reusing metal waste, as well as reducing carbon emissions, are crucial for a greener and more sustainable future for the industry.

- Virtual Reality (VR) and Augmented Reality (AR)

VR and AR technologies are finding applications in training, maintenance, and design in metal manufacturing. They allow workers to receive virtual training, visualize complex processes, and even perform remote maintenance. These technologies enhance safety, efficiency, and knowledge transfer in the industry.

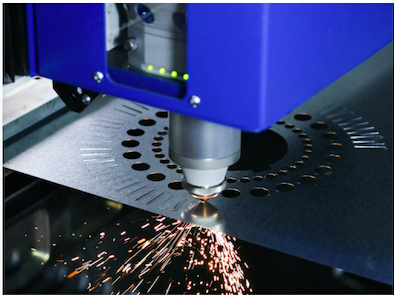

- Laser Cutting and Welding:

Laser technology is advancing rapidly, and its applications in metal manufacturing are expanding. High-precision laser cutting and welding processes offer benefits in terms of speed, accuracy, and quality. These processes are particularly important in the automotive, aerospace, and electronics sectors, where precision and quality are paramount.

- Nanotechnology

Nanotechnology is bringing significant advancements to the world of metal manufacturing. By manipulating materials at the nanoscale, manufacturers can create metals with improved mechanical and electrical properties. Nanocoatings can enhance a metal’s resistance to wear and corrosion, making them ideal for critical applications.

- Artificial Intelligence (AI)

AI is aiding metal manufacturers in process optimization, predictive maintenance, and quality control. Machine learning algorithms can analyze vast amounts of data to identify trends and anomalies, leading to better decision-making and improved efficiency.

- Customization and Personalization

Consumer demands for customized and personalized products are on the rise. Metal manufacturers are adapting to this trend by incorporating technologies that allow for mass customization, enabling the creation of unique metal components tailored to individual needs.

In conclusion, the future of metal manufacturing is an exciting landscape of innovation and transformation. As technology continues to evolve, the industry will be shaped by additive manufacturing, smart factories, advanced materials, robotics, sustainability, VR/AR, laser technology, nanotechnology, AI, and the demand for customization. These trends and technologies are set to drive the metal manufacturing sector towards greater efficiency, sustainability, and competitiveness in the global market. As these advancements continue to unfold, it’s essential for companies in the industry to stay informed and embrace these changes to remain at the forefront of metal manufacturing.